Production

The cylinder mould machine process

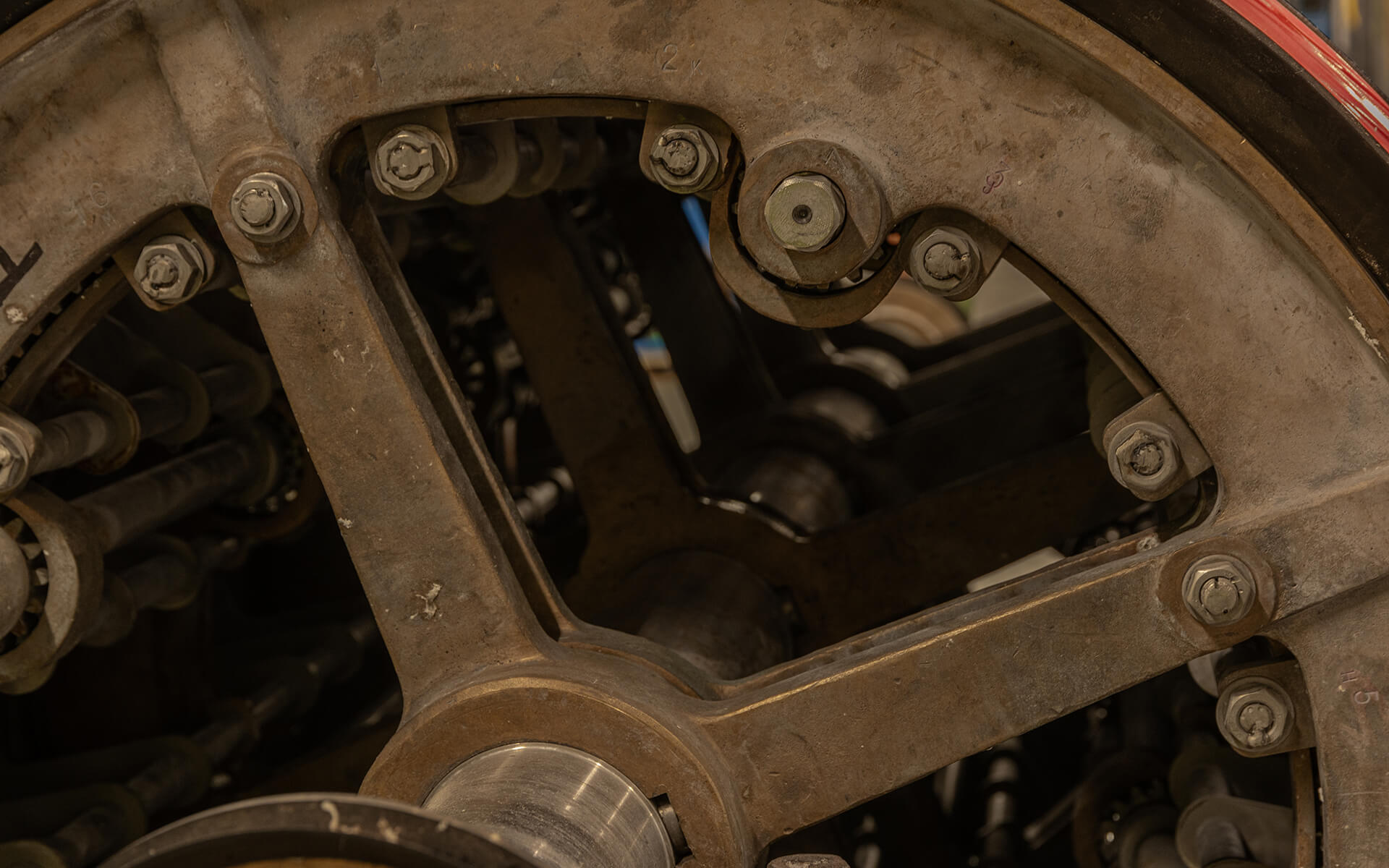

The traditional production process of the cylinder mould machine mimics the techniques of the master papermakers of the past, coming as close as possible to the original quality of handmade paper and producing distinctive deckle edges on all four sides. The production pace is slower than on the fourdrinier machine, allowing the fibres to settle evenly, resulting in smooth, even paper. Cotton pulp is spread evenly over a rotating cylinder mould made of fine wire mesh, which allows the water to drain off while the cotton fibers settle on the surface to form the paper.

The raw materials

The paper produced by Magnani 1404 on a cylinder mould machine is made using cotton fibres of highest quality. This allows high quality paper to be produced by drawing on the distinctive features of cotton, namely its purity and consistency: the long fibres of this material add strength and durability to the paper. Moreover, cotton creates a uniform, stable and absorbent surface, making prints or paintings stand out in crisp detail. Magnani 1404 papers are made of 100% cotton or a premium blend of cotton and alpha cellulose, making them suitable for all the main artistic applications: watercolour, acrylic, drawing, sketching, traditional art printing, luxury paper products and limited edition art books.

Sizings

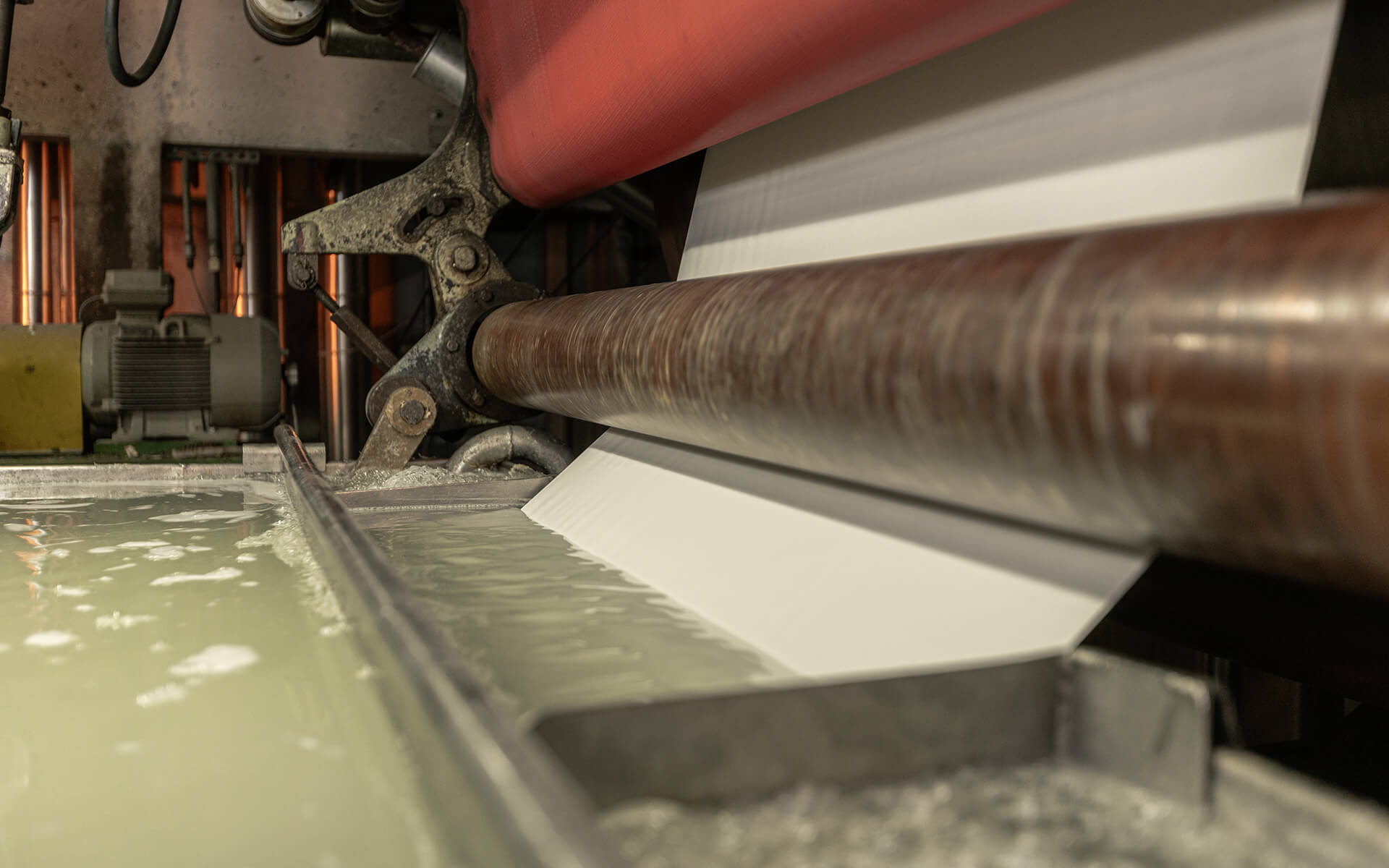

All Magnani 1404 papers are Vegan Friendly, as only plant-based sizing is used, containing no substances of animal origin. The paper is sized at this stage of production, that is a process that gives the paper sufficient resistance to liquids, thus limiting the absorption of ink or water and keeping the shade and vibrancy of the colours applied over time. Magnani 1404 papers undergo this process either in mass or on the surface, depending on their end use. Using the cylinder mould machine production method, the paper can be immersed in a bath of sizing solution allowing the treatment to penetrate deep into the cotton fibres, improving its overall performance.

The watermark

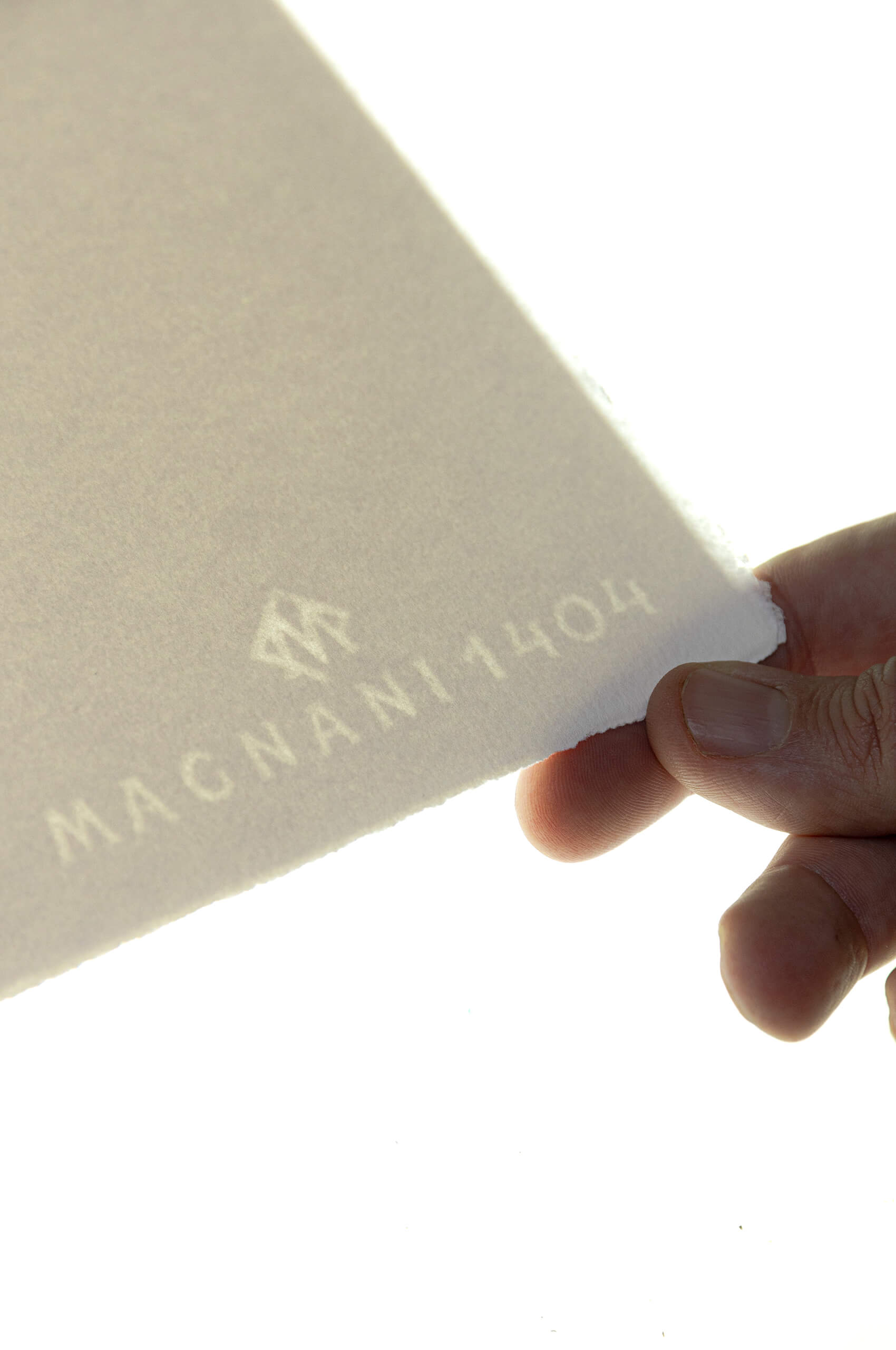

Working with the cylinder mould machine allows all papers in sheets by Magnani 1404 to be watermarked, an essential element in guaranteeing the authenticity of our products. Applying a design and/or mark to the cloth of the moulding cylinder creates a relief pattern that automatically generates a thinner layer of fibres at that point during manufacture by marking the still wet stock. Once dry, the watermark is clearly visible by backlighting the sheet of paper.

Finishing and binding into blocks and pads

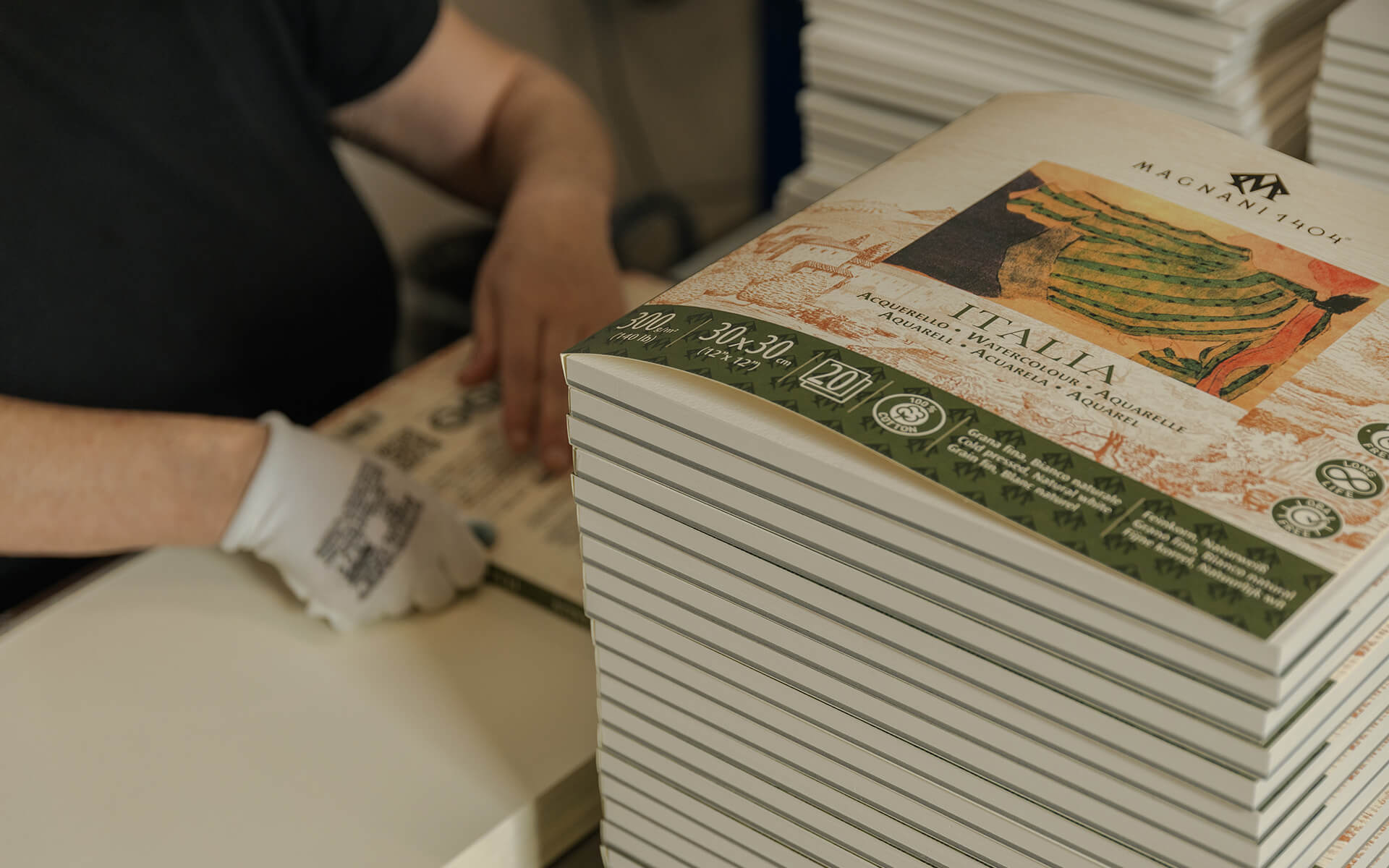

The sheets of paper undergo finishing processes that give them the required specifications, they are then either packed into packs of sheets or cut to the correct size and assembled into blocks or pads. Each pad (glued on 1 side) or block (glued on 4 sides or round) is hand-bound by expert papermakers: this guarantees a consistently high-quality standard for each individual product. Famous for their superior quality and performance, Magnani 1404 pads and blocks are now used for a wide variety of applications by artists all over the world.

© Copyright 2024. All rights reserved.

Fedrigoni S.P.A. - P.Iva 0166460223